TECHNICAL ADVANTAGE

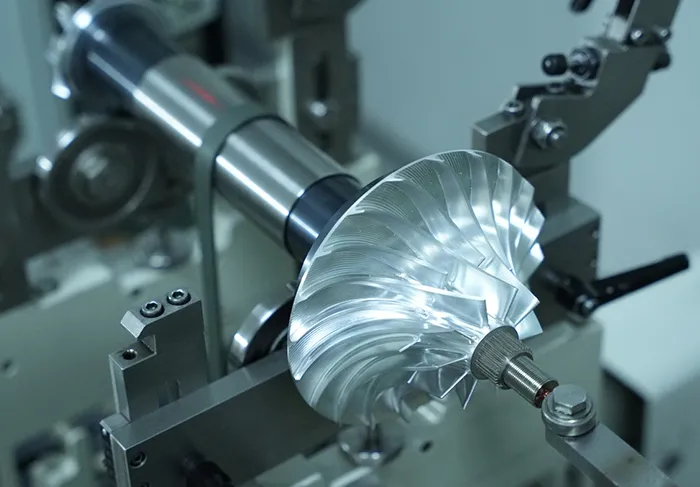

Centrifugal Impeller

Aerodynamic efficiency ≥85%

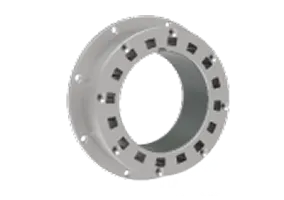

Air Foil Bearing

No physical contact

Oil-free

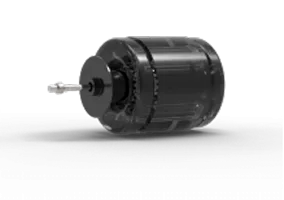

PM Motor

Efficiency ≥98%

Speed up to 200,000 rpm

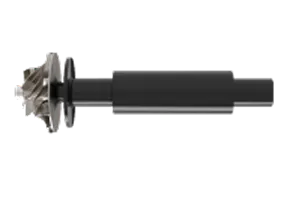

Direct-Drive Rotor

Super wear-resistant coating

Start/stop cycle> 580,000

FAQ

The growing need for energy conservation and carbon footprint reduction across a range of industries are driving revolutionary dynamics in the high-speed turbo blower & compressor market, with the introduction of the advanced high-speed permanent magnet synchronous motor and high-frequency converter. This technology requires very high rotation speed up to 70,000rpm, relying on non-contact bearing technology, either air bearing or magnetic bearing, but which one is better?

In magnetic bearing technology, the shaft's position is measured by position sensors continuously, which is more complex to ensure precise control. To prevent the rotor damage once the power failure, the circularly arranged solenoids require a UPS, to control the shaft down the rotor speed to a safe level and land on the mechanical backup bearings till it comes to a halt.

However, the UPS (battery) is not maintenance-free and might be malfunction at higher temperatures or when magnetic fields fail. The magnetic bearings' backup system only functions at extremely low speeds. That means a high-speed turbo blower with magnetic bearing is highly prone to damage at very high speeds, like during recurrent power failures without a sufficiently charged battery system.

In air bearing technology, which operate on a simple physical principle, when the rotor begins to accelerate, the air foil between the shaft and the journal bearing levitates the shaft by Dynamic Pressure, which generates a Wedge effect. As the rotating speed increases, the Surrounding air pressure will hold the rotor in the center contact-free position. The bearing applied a double-layer coating technology, adding Nano Silver particle coating layer to the existing Teflon (PTFE) coating, aimed at enhancing both wear resistance and adhesive force, our patent technology will guarantee 580,000 start-stop cycles.

To summarize, the top priority for customer operation is to get highly efficient turbo product with minimal maintenance and operating costs. Magnetic bearings' complex design makes it mor expensive, more prone to problems and maintenance is needed, significantly increasing life-cycle costs. On the other hand, air bearing systems don't require any mechanical, pneumatic, or electrical controls. That's why a high-speed turbo blower or compressor with air bearing system is more energy efficient, cost-effective, and requires minimal maintenance.

Over 19 years of experience in designing, manufacturing, and servicing air bearing products, ZCJSD believes in air bearing as our standard non-contact high-speed turbo solution.

Don't hesitate to contact us if you need further information on our high-speed turbo blowers & compressors.

MAINTENANCE AND UPKEEP

Horizontal state of equipment installation

The tightness of the air end on the frame.

The isolation and condition of electrical equipment.

The condition and tightness of electrical connections.

Control of coolant levels.

Operation of the alarm safety devices.

Replacement of air filters.